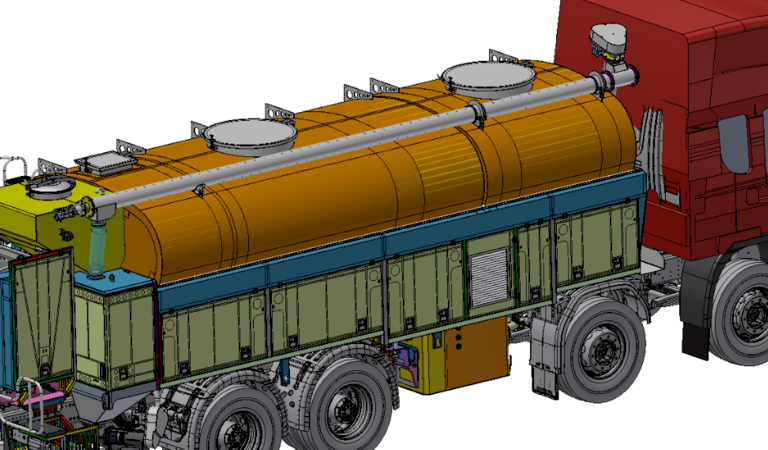

UMS (Universal-Mixing-System)

preparation and sensitizing of emulsion, production of ANFO or Heavy-ANFO on-site with SMS or RPS technique

MEMU Features

-

- System is completely MEMU certified

- System adaptable to most chassis from all suppliers; current available standard is built on SCANIA.

- Key Components (such as pumps) customizable to match individual requirements.

- Adjustable production rate: to up to 300 kg/min (standard 100kg/min)

- Capacity: up to 18tons due to new design

• Universal Mixing

• Loading distance 20-80 meters, (others on demand), • Hose diameter from 0,5 inch to 2 inch.

MEMU Features

-

- Dosing of all relevant product components is monitored and controlled by electronic instruments such as mass-flow meters.

- Hand-picked choice of materials for the complete equipment based on experience and special considerations in order to ensure long lasting and reliable durability!

- (f.i. stainless steel and special plastic components such as PP HD and PEEK)

- Arctic version: Optional complete Isolation of vessels and hatches ensures workability in

any environment of -40°C to +50°C (Aluminum Emulsion tank can be supplied for Scandinavia)

Safety Systems as per MEMU / ADR

-

Mechanical and electronic safety control for pressure and temperature

-

Automatic fire extinguishing system (ANSUL)

-

Redundant design of all relevant control systems

-

Rupture discs

User friendly features

-

Easy access to relevant equipment and instruments

-

High pressure cleaner included

-

„Self-cleaning“ tank-shape

-

Closed and secured stowage and control elements

-

Design concept allows quick replacement of relevant components for on-site repairs.

-

Network / Internet access to all control and monitoring systems